Label Industry Evolution: Overcoming Supply Chain Disruptions and Improving Efficiencies in the Post-Pandemic World

The label industry has faced significant supply chain disruptions in recent times, with COVID-19-related shutdowns and worker strikes causing major delays in production and delivery. Despite these challenges, the industry has made impressive strides in improving materials and supply chain efficiencies, resulting in reduced backorder times and greater reliability for customers. In this article, we will examine some of the key factors driving these changes and explore the outlook for the label industry in the post-pandemic world.

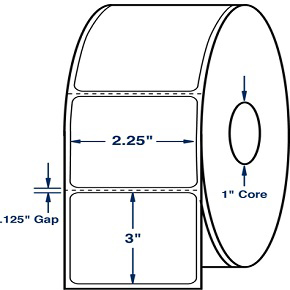

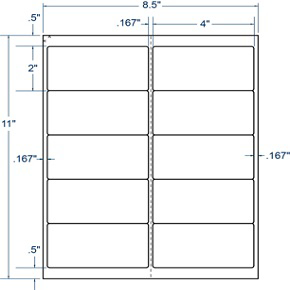

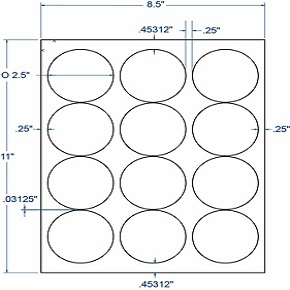

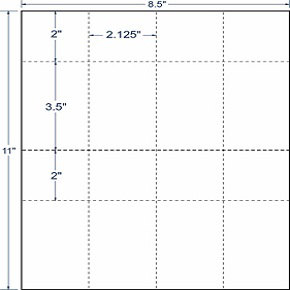

First, let's take a closer look at the label industry itself. Labels are essential components of almost all products and packaging, and they play a critical role in communicating information to consumers. Labels are used to convey essential information such as product ingredients, usage instructions, and safety warnings. Additionally, they can also serve as branding elements, helping to differentiate products and create a strong visual identity for a particular brand.

Given the importance of labels, it's not surprising that there is a significant demand for high-quality labels that are durable, visually appealing, and able to convey important information accurately. However, producing labels that meet these criteria can be a complex and challenging process, involving a wide range of materials, production methods, and supply chain factors.

One of the most significant trends in the label industry in recent years has been a shift towards more sustainable materials and production methods. Consumers are increasingly concerned about the environmental impact of the products they buy, and labels are no exception. Many label manufacturers are now working to develop more eco-friendly solutions, such as labels made from recycled materials or biodegradable substrates.

At the same time, supply chains in the label industry are also evolving, with a greater focus on reducing backorder times and improving overall efficiency. One factor driving these changes is the increasing use of just-in-time (JIT) manufacturing and supply chain management approaches. With JIT, manufacturers only produce goods in response to customer demand, reducing the need for excess inventory and helping to improve overall efficiency and reduce costs.

In addition to JIT, many label manufacturers are also working to streamline their supply chains by implementing more advanced tracking and logistics systems. By using real-time data to monitor inventory levels, production schedules, and shipping logistics, manufacturers can better anticipate demand and respond more quickly to changes in the market.

Overall, the label industry is undergoing significant changes as manufacturers adapt to new materials, production methods, and supply chain models. With a greater focus on sustainability and efficiency, we can expect to see even more innovation in this space in the years ahead. And as backorder times continue to decrease, consumers can look forward to more timely and reliable access to the high-quality labels they rely on.